Why Choose Us

We are focusing on "Balance".

We are a professional and specialized manufacturer.

Established in 1974 in Sakai, Osaka, we, Denshi Seiki Kogyo K.K. (DSK), celebrate our 50th anniversary in 2024.

For half a century, we have been developing and manufacturing "Balance testers" and "Balance correction machines" for measuring and correcting the balance of rotating parts (armatures) of motors used in automobiles, home appliances, and power tools, etc.

We have earned the trust of many of our customers through our careful custom-made manufacturing to meet their needs.

Based on our success in Japan, we established a factory in Suzhou, China in 2002.

We are also expanding our overseas operations, including a distributor in South Korea to provide local support.

We will continue to respond to our customers' challenges and detailed requests that other companies cannot meet.

We will contribute to our customers' production with advanced technical capabilities and valuable suggestions.

What is balance?

"Balance" is a measure of whether the center of gravity is in balance with the central axis of the rotating parts.

Just as an unbalanced bicycle wheel, for example, can cause it to sway more or go slower, the balance of rotating parts not only affects the performance and comfort of a product, but also causes failure and damage.

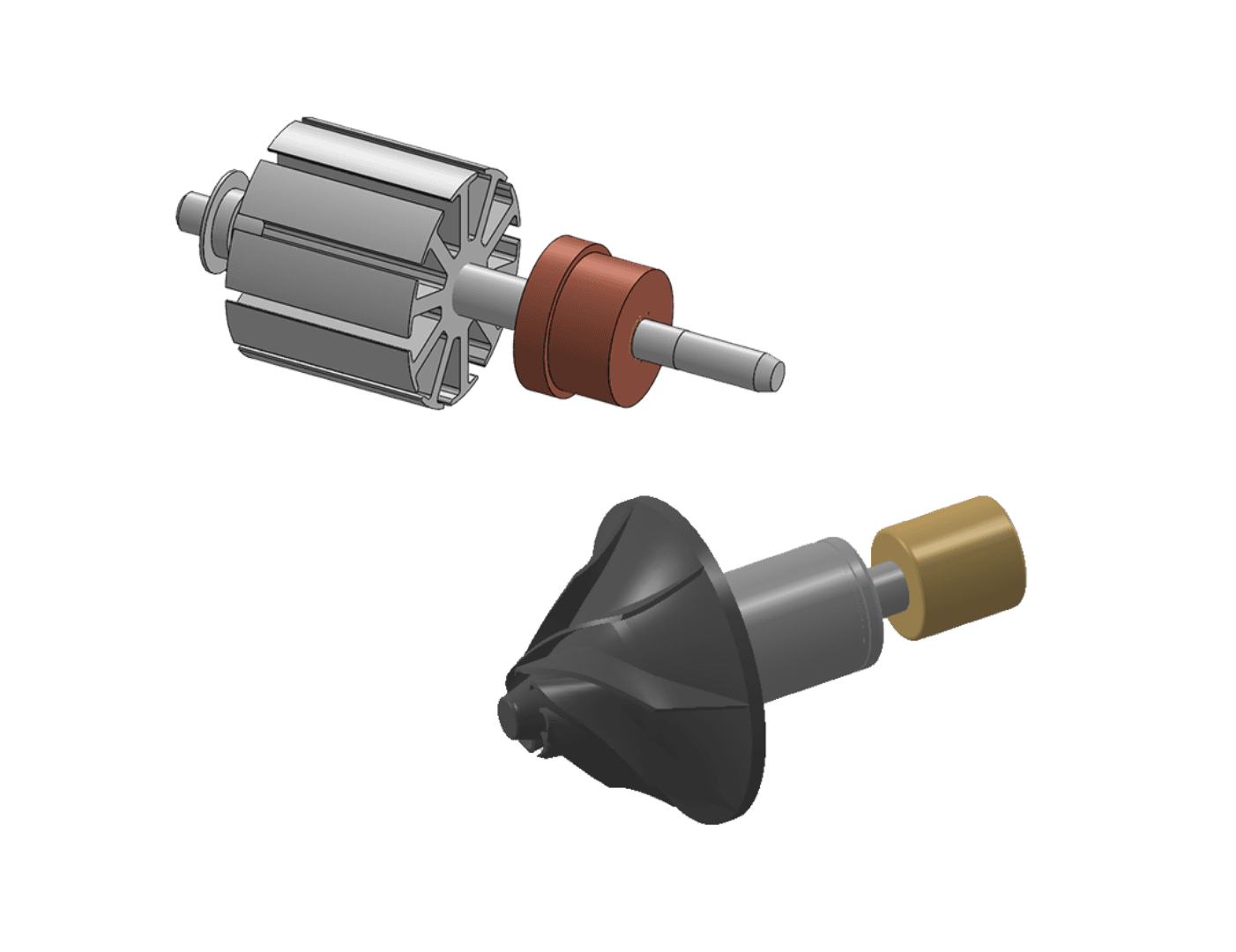

Motors have a rotor. The rotor is made of metal, plastic, coil or coating material, and although it is designed to be even, the center of gravity does not necessarily match the center of the axis of rotation.

This state of imbalance is called "unbalance".

In order to produce high quality products, it is essential to measure and correct unbalance and keep the balance within the standard values.

Although the Japanese Industrial Standard (JIS) also has regulations for balance (B 7737-1995), in practice it is common for customers to have their own standards.

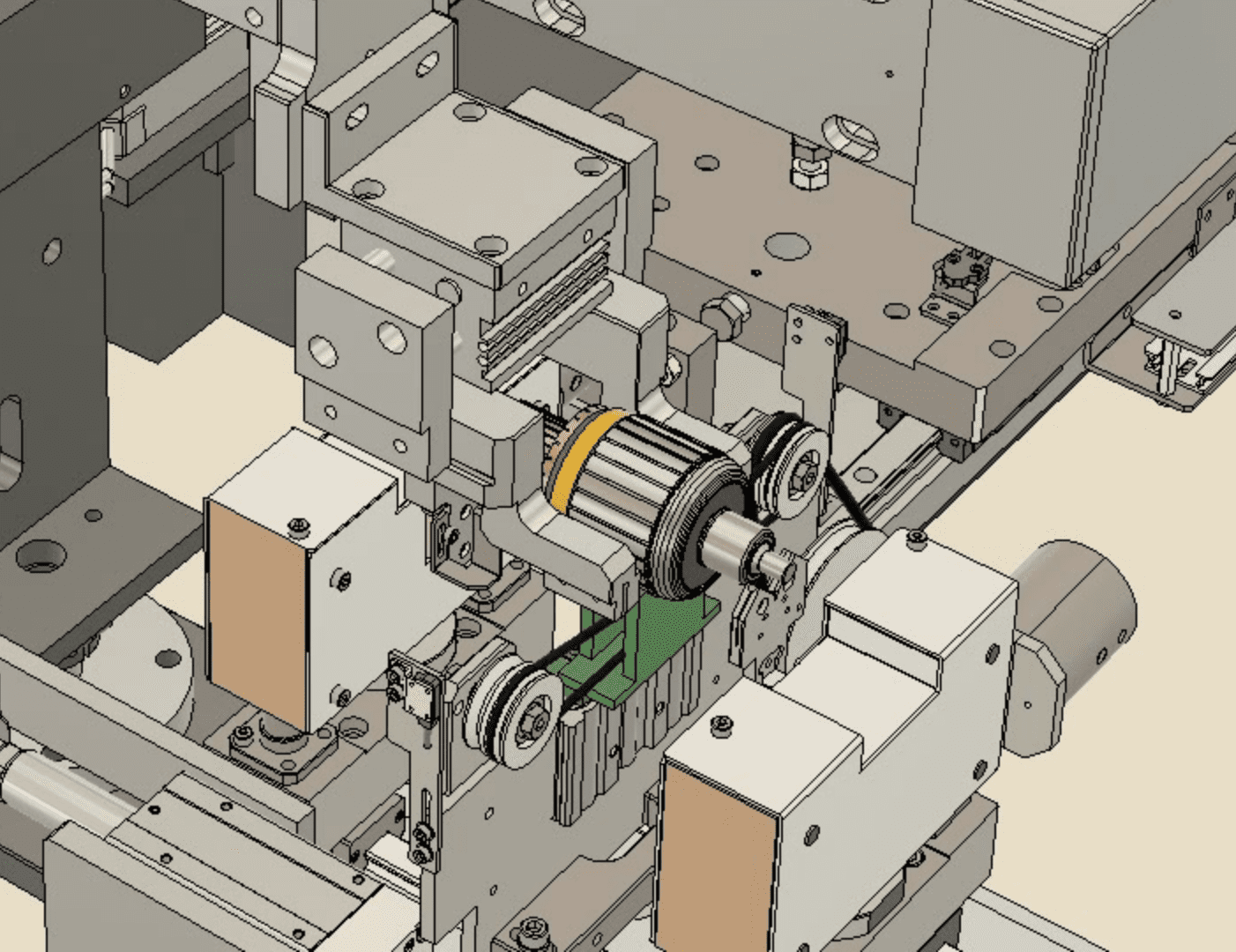

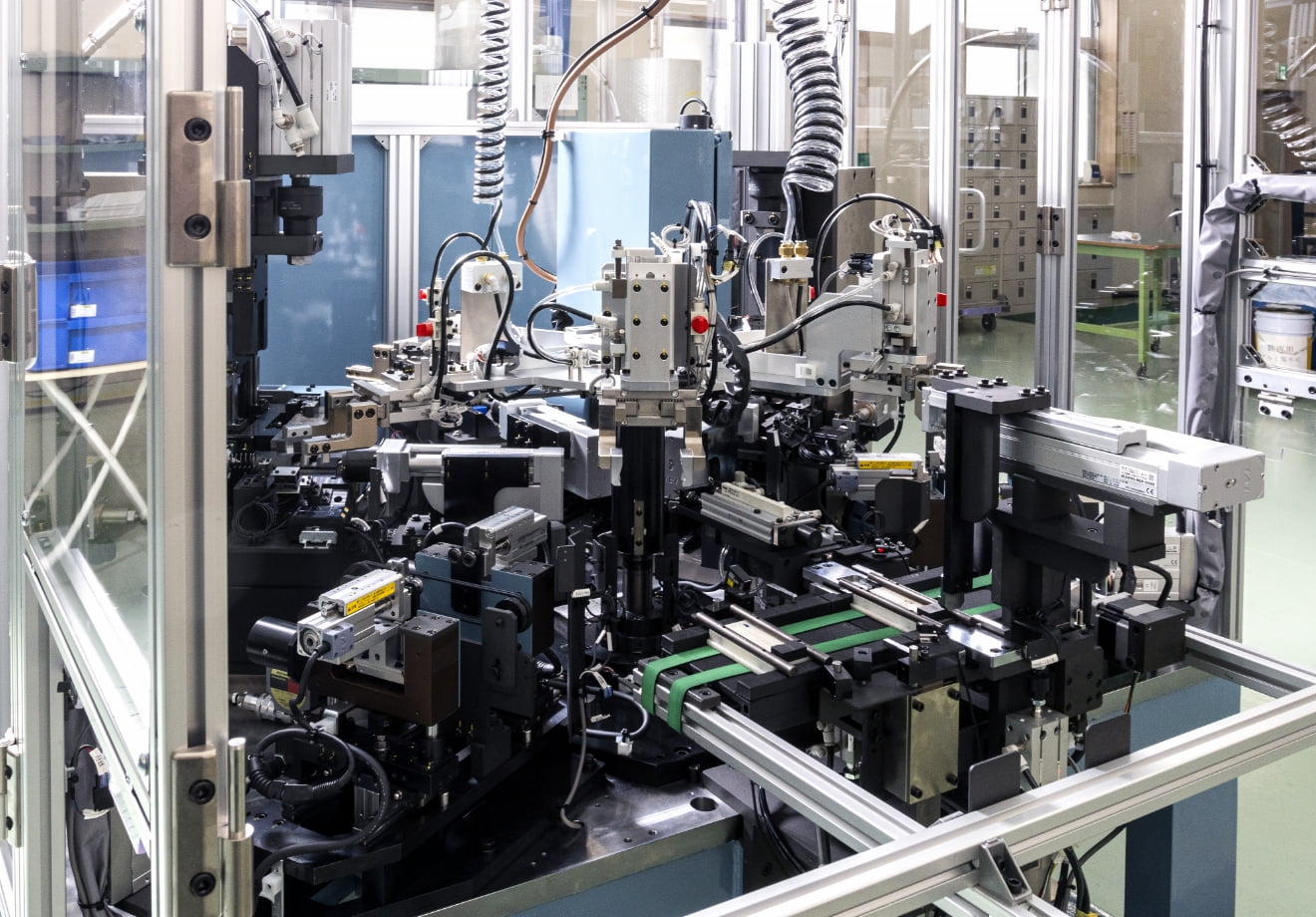

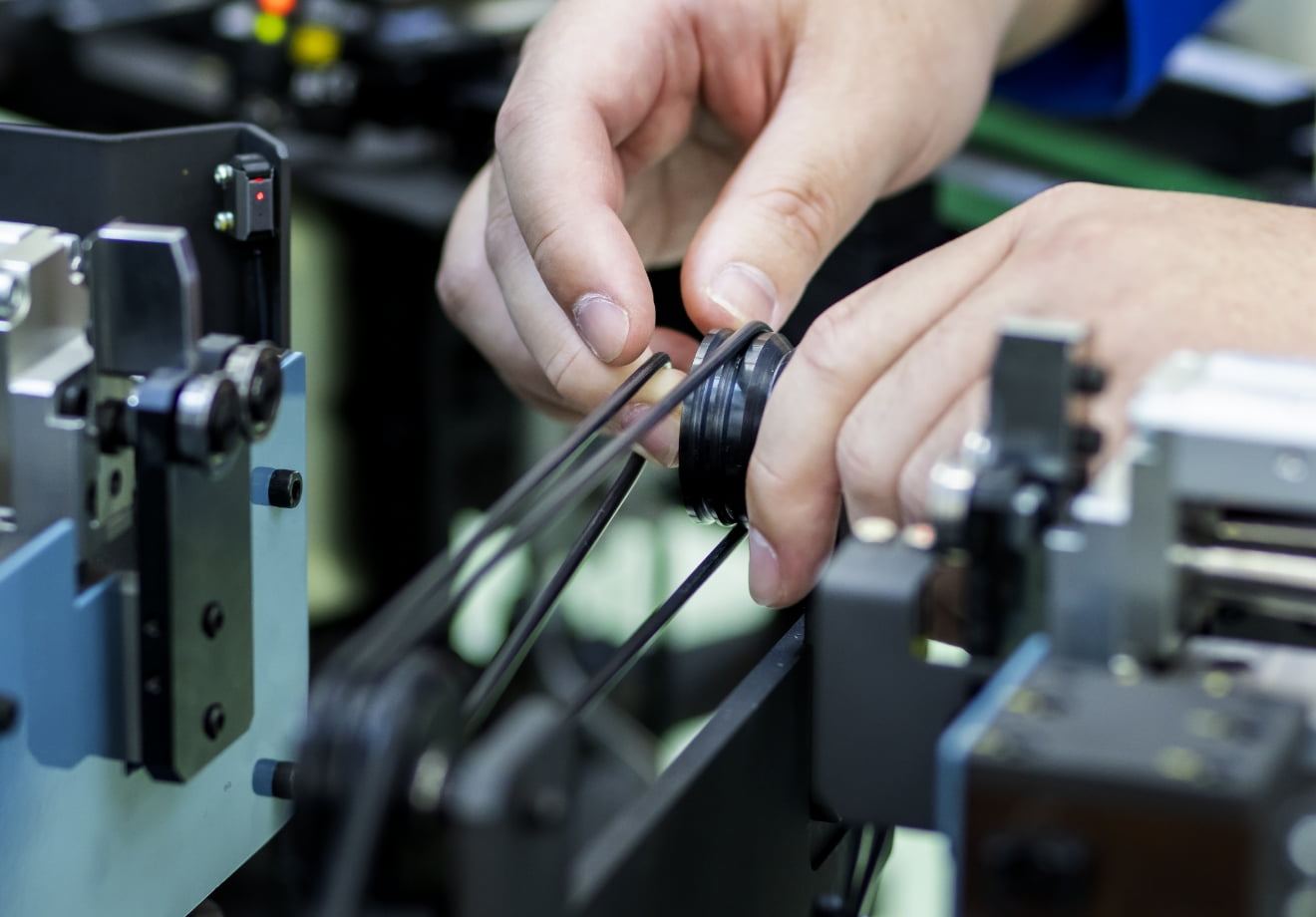

The "Balancing Machines (Balancing Tester)" and "Balance Correction Machines" we develop and manufacture rotate the workpiece to be measured (workpiece to be machined) to measure vibration and detect the point, angle and amount of its occurrence.

The measurement data is analyzed to determine the balance and corrections are made either manually or automatically.

By eliminating unbalance, we can reduce wear, vibration and noise, extending product life and contributing to our customers' quality manufacturing.

DSK Advantage

Full range of proposals and support capabilities

as a specialized manufacturer

-

Sales · Proposal of specification

- We will propose the necessary specifications based on our many years of experience.

- It is possible to prepare quotations according to the customer's original specifications (safety and other standards).

-

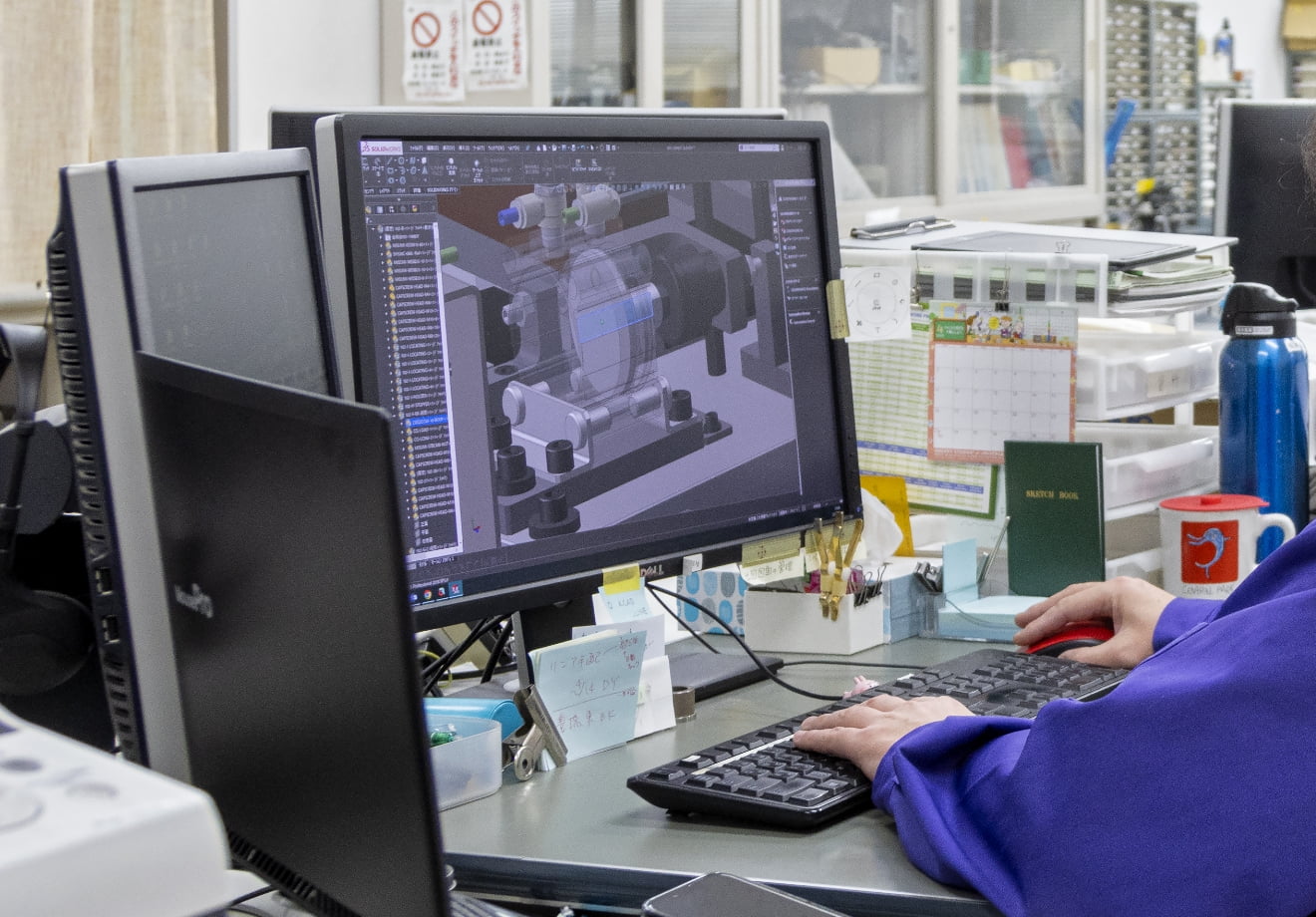

Design · Manufacturing

- Our machines are designed to reduce setup time with simple tooling.

- We produce machines that can be maintained by overseas customers through phone and e-mail support.

-

Delivery · After-Sales Service

- Adequate machine testing and inspection at our factory minimizes machine start-up time after production line assembly.

- After-sales service is available in Japan and overseas. Please contact us for details.

DSK 3 features

Reliable technical capabilities to achieve fast, high-precision measuring

We, DSK, not only design and manufacture machines, but also develop our own software and measuring units with dedicated circuit boards in an integrated manner.

This enables fast and accurate balance measurement.

We provide solutions to customers' unique requirements and technical issues from both hardware and software perspectives and propose the best machine.

Extensive track record trusted by top manufacturers for many years

DSK machines have been used for many years on the production lines of Japan's top automotive parts manufacturers and home appliance manufacturers.

We can produce unique machines with the flexibility to meet customer's operating specifications and safety standards.

However, this is not enough for true trust.

The stability of the machine itself is also necessary to support the stable operation of the production line.

DSK machines are highly regarded by our customers' on-site managers for their durability and ease of maintenance, and for their ability to support a stable line.

High maintenance design for ease of field serviceability

Machines that require high-precision balance measurement and correction need parts replacement and adjustment at a certain frequency.

Therefore, it is important to consider field maintenance when designing a machine.

DSK machines are designed for easy on-site maintenance based on years of experience.

Therefore, it can be safely used in both domestic and overseas production lines.

Development · Workpiece examples

We can manufacture and delivery of machines for the following workpieces

- Power generation and drive motors for hybrid and electric vehicles

- Fuel pump motor for engines

- Motors used in home appliances (Vacuum cleaners, Washing machines, etc.)

- Motors used for power tools

Please contact us for other workpieces.